Having filtration systems available for oil mists is an essential aspect of ensuring cleaner and safer production in various industrial sectors. Oil mists can pose a threat to workers' health and the efficiency of the facilities.

In this article, we will explore the importance of capturing oil mists and provide a comprehensive guide for implementing effective filtration systems.

What are oil mists?

Oil mists consist of airborne oil particles that are primarily formed during mechanical processing, such as cutting oils, coolant fluids, and lubricants. These particles can be extremely small and invisible to the naked eye, but they can have serious health effects if inhaled by workers.

But that's not all: oil mists can also deposit on the surfaces of equipment, damaging the electronic components of machine tools and reducing their efficiency.

How are oil mists formed?

Oil mists are formed through lubrication and cooling processes that cause the vaporization of oils and emulsions. High temperatures cause combustible oils to transition from a liquid phase to a gaseous phase, allowing microscopic particles to disperse rapidly and easily as oil mists in the work environment.There are numerous applications that require filtration systems for oil mists, including:

· Turning: Oil mists are generated when the lubricant used to reduce friction and improve cutting precision vaporizes due to the high temperatures generated by the rotational movement of the tool and the workpiece.

· Milling: In this case, oil mists are formed when the coolant fluid used to cool and lubricate the milling process is affected by the heat generated by the cutting action, resulting in vaporization and particle diffusion.

· Drilling: The lubricant used to reduce friction and dissipate heat generated by the drill bit evaporates, producing oil mists.

· Grinding and finishing: Oil mists are produced during these processes due to the vaporization of the lubricant or coolant fluid used to cool and lubricate the tool and workpiece.

· Threading/Tapping: Threading or tapping generates oil mists when the lubricant or cutting oil used to reduce friction and improve thread formation evaporates.

· Metal cleaning machines: They can produce oil mists when the lubricating oil or detergent fluid used in the cleaning process vaporizes due to the high temperatures of the water and chemicals used.

Abate oil mists through coalescence filtration

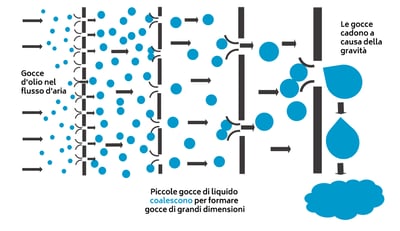

When it comes to reducing oil mists, coalescence filters are the most widely used and effective solution. Coalescence is a natural phenomenon where microparticles of the same substance gather together to form larger particles with increased volume and weight.

Coalescence filters leverage this principle to separate oil mist particles from the air. The particles coalesce inside the filter, allowing them to fall into a designated container. As a result, the air within the work environment will be free from polluting oil mists.

HFiltration: Advanced Filtration Systems

HFiltration offers three different technological solutions for eliminating oil mists:

• Centrifugal Filters (CleanMist): These compact filters can be easily installed directly on machine tools. They utilize centrifugal force to separate oil mist particles from the air, ensuring effective cleaning.

• Centralized Filters (Mist Compact): This solution is ideal for centralized systems where oil mists from various sources need to be treated. It employs a coalescence effect to separate emulsified oil particles from the air, ensuring efficient purification.

• Coalescence Filter for Heavy Mechanical Processing (MCOS): This filter is designed to handle demanding mechanical processes that use full oil and generate smoke. It leverages the coalescence principle to separate oil and smoke particles from the air, providing an effective solution even in particularly challenging working conditions.

Regardless of your company's specific needs and operations, HFiltration has the suitable solution to ensure a clean and safe working environment.

Investing in filtration systems means ensuring the health and safety of workers, as well as compliance with environmental regulations.

Contact our experts for personalized consultation and discover how to improve air quality in your workplace.